Quality

We work in an Integrated quality and environment management system that was implemented in the year 2000. They also meet the requirements of IATF 16949:2016 the automotive sector. FMEA operates for each of the implemented process. The SPC and MSA process capabilites for control and measurement equipment are tested. New conditions are implemented based on APQP and PPAP. Internal system and process audits along with products are carried out by qualified auditors.

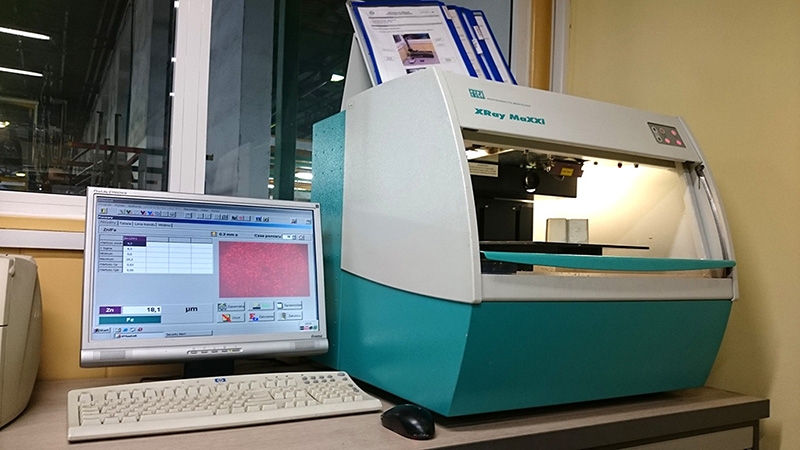

Laboratory

We have a chemical lab and a measuring lab, in which qualified personal regularly monitor working tub parameters, they run analysis, tests and check surface coatings.

Our lab is equipped with:

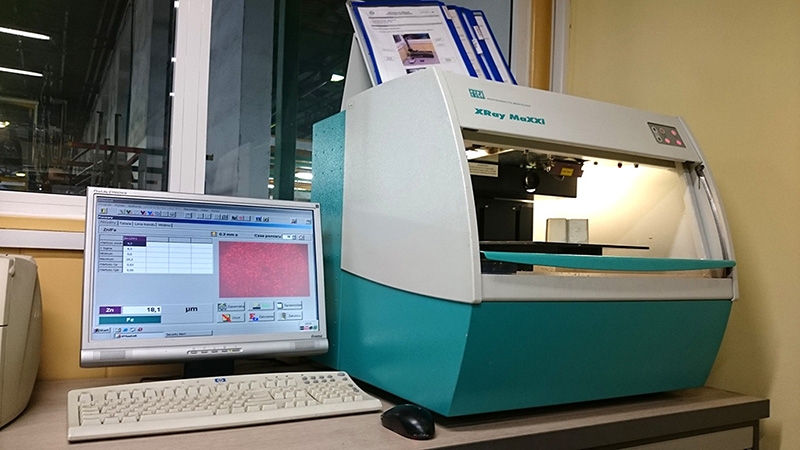

- X-ray: it measures the thickness of zinc coating, the amount of nickel in the coating along with analizying the plating baths.

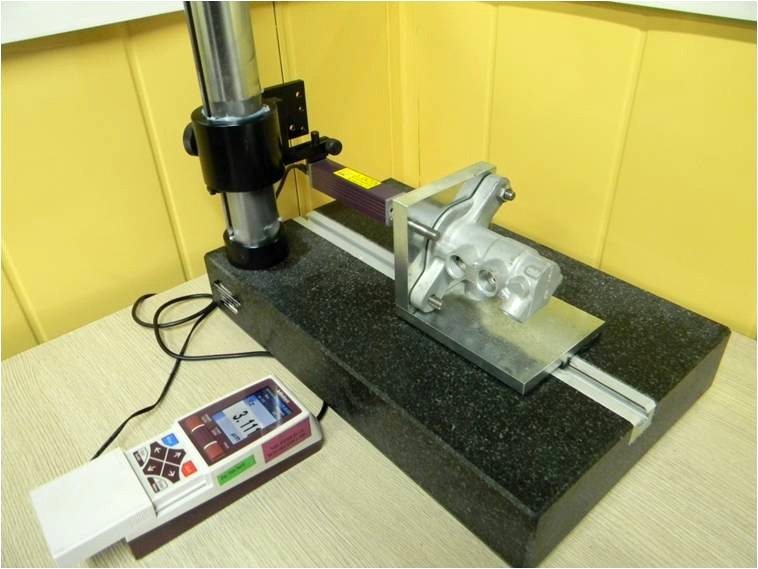

- MITUTOYO : measures surface roughness

- Ultrometers, micrometers, transameters calibrated on verified standards\

- Spectrophotometer XION500 – analizes number of and quality of baths

- HULLA cell – measures the depth and efficiency of the baths.

- InoLab Multi 9630 WTW meter – it measures pH levels, conductivity and ISE

- Precision scales and test weights

- Electronic thermometers and temperature regulators

- Driers with forced circulation

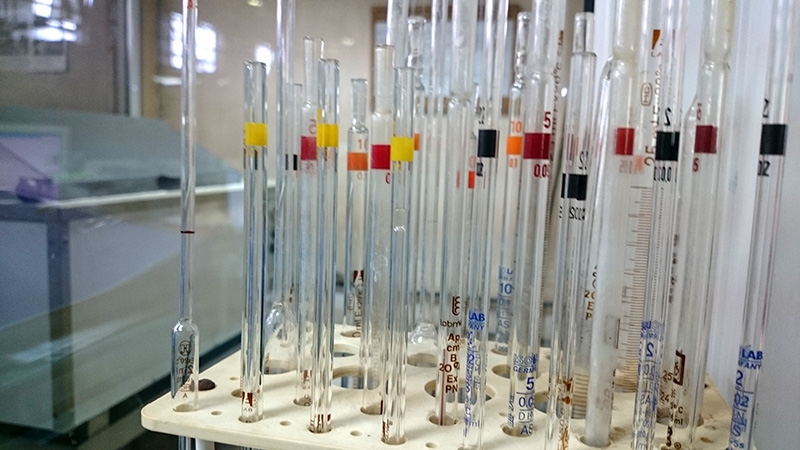

- Automatic pipettes, appropriate laboratory glass that is dedicated to specific bath analysis

- Salt chamber – corrosion resistance testing